Mokhoa oa Tlhahiso

Mokhoa oa tlhahiso eaTerry Fabric Circle Loha Mechinike tatellano e rarahaneng ea mehato e etselitsoeng ho hlahisa masela a boleng bo holimo a terry. Masela ana a khetholloa ke mehaho ea bona e nang le looped, e fanang ka mokhoa o babatsehang oa ho noa le ho bopa. Mona ke ho sheba ka botlalo ts'ebetso ea tlhahiso:

1. Tokisetso ea Lintho :

Khetho ea likhoele : Khetha likhoele tsa boleng bo holimo tse loketseng tlhahiso ea masela a terry. Likhetho tse tloaelehileng li kenyelletsa k'hothone, polyester le likhoele tse ling tsa maiketsetso.

Khoele Feeding : Laela khoele holim'a tsamaiso ea creel, ho netefatsa tsitsipano e nepahetseng le ho lumellana ho thibela khefu le ho netefatsa phepo e tsitsitseng.

2. Tlhophiso ea Mochini :

Tlhophiso ea nale : Beha linale ho ea ka tekanyo ea lesela le lakatsehang le mohlala. Mechini ea ho loha ea Terry hangata e sebelisa linale tsa latch.

Phetoho ea Cylinder : Fetola silinda ho bophara bo nepahetseng 'me u netefatse hore e tsamaisana hantle le lesale la ho teba le litsamaiso tsa cam.

Calibration ea Cam System : Lekola litsamaiso tsa cam ho laola motsamao oa linale le ho fihlela mokhoa o lakatsehang oa ho roka.

3. Mokhoa oa ho loha :

Khoele ea ho Fepa : Khoele e feptjoa ka mochine ka li-feeders tsa khoele, tse laoloang ho boloka tsitsipano e tsitsitseng.

Ts'ebetso ea Nale : Ha cylinder e ntse e potoloha, linale li etsa loops ka khoele, li etsa lesela. Li-sinkers li thusa ho tšoara le ho lokolla loops.

Loop Formation : Li-sinkers tse khethehileng kapa linale tsa crochet li lelefatsa lesela le tebileng la lesela ho etsa loops.

4. Taolo ea Boleng :

Tlhokomelo ea Nako ea 'Nete : Mechini ea sejoale-joale e na le lits'ebetso tse tsoetseng pele tsa ho lekola tse latellang boima ba masela, elasticity, boreleli le botenya ka nako ea nnete.

Liphetoho tse Iketselitsoeng : Mochini o ka ikamahanya le maemo ho boloka boleng bo lumellanang ba lesela.

5. Kamora ho sebetsa :

Thepa ea Lesela : Lesela le lohiloeng lea bokelloa ebe le kenngoa holim'a batch roller. Sistimi ea ho theola e tiisa hore lesela le lemetse ka ho lekana.

Tlhahlobo le Packaging : Lesela le phethiloeng le hlahlojoa ho bona mefokolo ebe lea pakoa hore le romeloe.

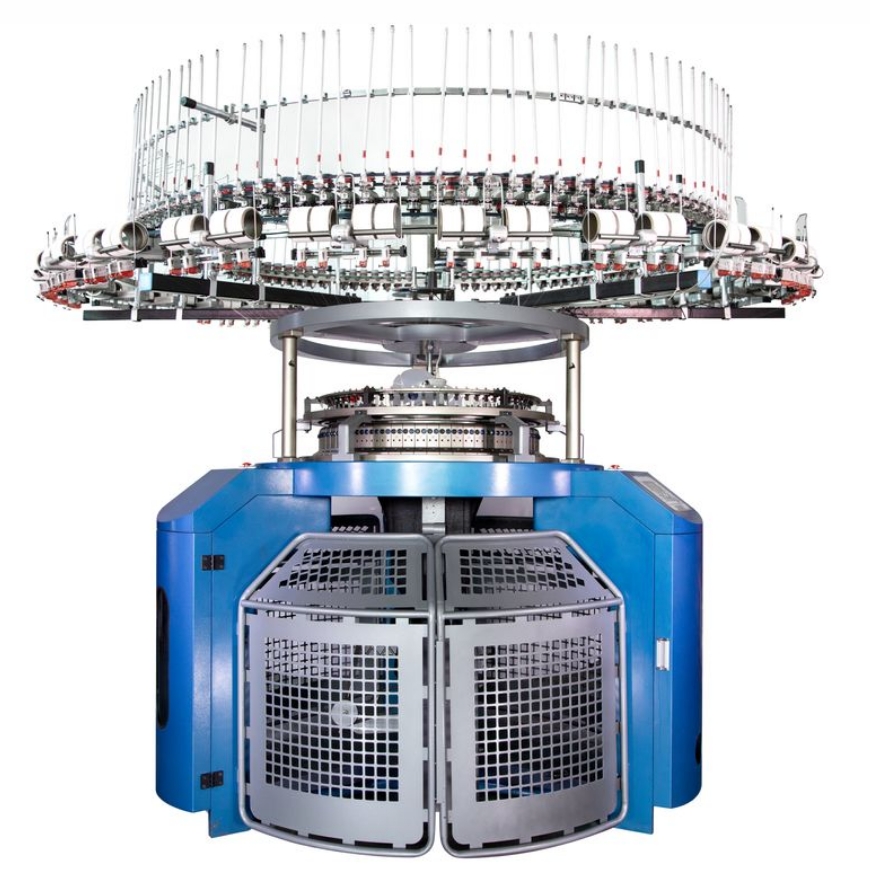

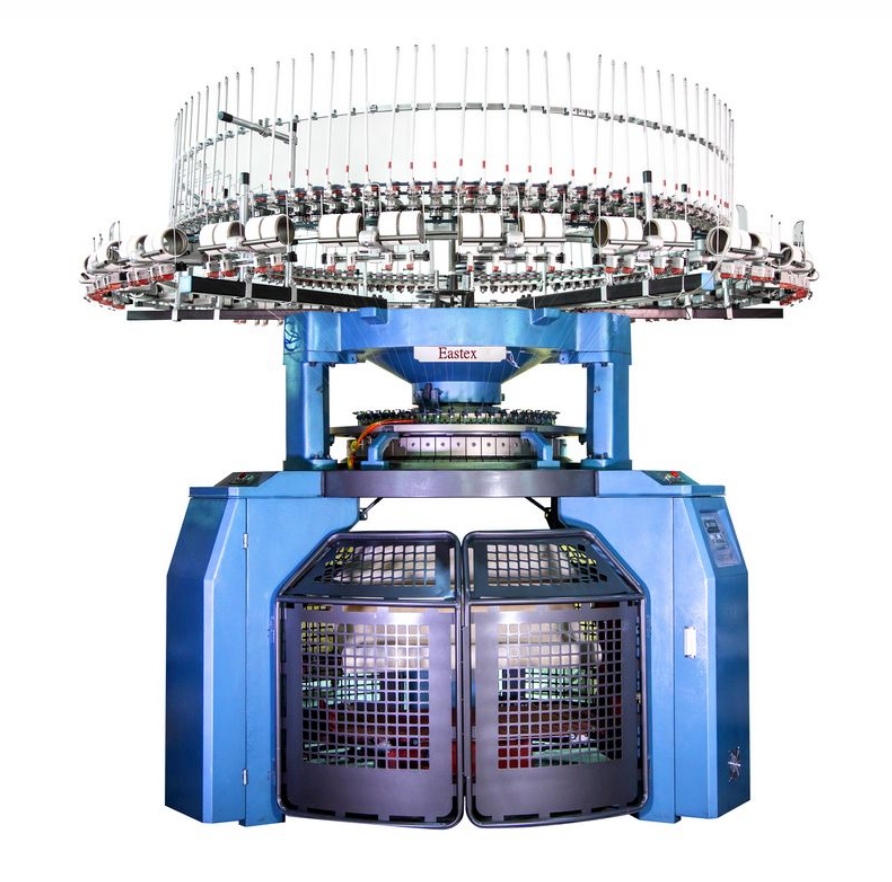

Likaroloana le Mesebetsi ea Tsona

1. Bethe ea nale :

Cylinder le Dial : Silinda e tšoara halofo e ka tlaase ea linale, ha mohala o tšoara halofo e ka holimo.

Linale : Linale tsa latch li atisa ho sebelisoa bakeng sa ketso ea tsona e bonolo le bokhoni ba ho sebetsana le mefuta e sa tšoaneng ea likhoele.

2. Lisebelisoa tsa likhoele :

Phepelo ea likhoele : Li-feeders tsena li fana ka khoele ho linale. Li etselitsoe ho sebetsa ka mefuta e fapaneng ea likhoele, ho tloha ho tse ntle ho ea ho tse ngata.

3. Sisteme ea Cam :

Taolo ea Paterone ea Stitch : Sisteme ea cam e laola motsamao oa linale mme e etsa qeto ea mokhoa oa ho roka.

4. Sinker System :

Loop Holding : Li-sinkers li tšoara likoti sebakeng sa tsona ha linale li ntse li ea holimo le tlaase, li sebetsa hammoho le lisebelisoa ho etsa mokhoa o lakatsehang oa ho roka.

5. Rola ea ho Nka Lesela :

Pokello ea Lesela : Rolara ena e hula lesela le phethiloeng ho tloha betheng ea nale ebe e le phetlela holim'a roller kapa spindle.

Tlhophiso

Terry Fabric Circle Loha Mechinitla ka litlhophiso tse fapaneng ho fihlela litlhoko tse fapaneng tsa tlhahiso. Litlhophiso tsa mantlha li kenyelletsa:

- Mofuta o le mong oa Needle Bed Multi-cam:Mofuta ona o sebelisoa haholo bakeng sa ho feto-fetoha ha oona le bokhoni ba ho hlahisa bolelele bo fapaneng ba loop.

- Mochini oa Weft Weft Weedle Bed Habeli: Moetso ona o sebelisa libethe tse peli tsa nale ho etsa loops ea bolelele bo fapaneng.

Tlhomamiso le Komisi

1. Tlhophiso ea pele :

Ho beha Mochine : Etsa bonnete ba hore mochine o behoa sebakeng se tsitsitseng le se lekaneng.

Phepelo ea Matla le Khoele : Hokela mochini ho mohloli oa matla 'me u thehe sistimi ea phepelo ea likhoele.

2. Calibration :

Needle le Sinker Alignment : Fetola li-needle le sinkers ho etsa bonnete ba ho lumellana hantle.

Tension ea khoele : Lekanya li-feeders tsa khoele ho boloka tsitsipano e tsitsitseng.

3. Liteko li matha :

Tlhahiso ea Mohlala : Tsamaisa mochini ka likhoele tsa liteko ho hlahisa masela a mohlala. Hlahloba lisampole bakeng sa ho tsitsisa ha stitch le boleng ba lesela.

Litokiso : Etsa liphetoho tse hlokahalang ho latela liphetho tsa liteko ho netefatsa ts'ebetso e nepahetseng.

Tlhokomelo le Tšebeletso ea Ka mor'a Thekiso

1. Tlhokomelo ea Kamehla :

Ho Hloekisa Letsatsi le Letsatsi: Hloekisa bokaholimo ba mochini le mokelikeli oa likhoele ho tlosa litšila le likhoele.

Litlhahlobo tsa Beke le Beke : Lekola lisebelisoa tsa ho fepa likhoele ebe u kenya likarolo tse seng li tsofetse.

Ho Hloekisa Khoeli le Khoeli : Hloekisa daela le silinda ka botlalo, ho kenyeletsoa linale le lisinki.

2. Tšehetso ea Theknoloji :

Tšehetso ea 24/7: Baetsi ba bangata ba fana ka tšehetso ea tekheniki ea bosiu le motšehare ho thusa ka litaba life kapa life.

Warranty le Litokiso : Litšebeletso tse felletseng tsa tiisetso le lits'ebeletso tsa tokiso e potlakileng li teng ho fokotsa nako ea ho theoha.

3. Koetliso :

Koetliso ea Opereishene : Hangata ho fanoa ka koetliso e felletseng bakeng sa basebetsi mabapi le ts'ebetso ea mochini, tlhokomelo le ho rarolla mathata.

4. Tiisetso ea Boleng :

Tlhahlobo ea ho Qetela: Mochini o mong le o mong o hlahlojoa ka lekhetlo la ho qetela, o hloekisoe le ho paka pele o romelloa.

Letšoao la CE: Mechini hangata e tšoauoa ka CE ho netefatsa hore e fihlella maemo a holimo a polokeho le ts'ebetso.

Qetello

Terry Fabric Circle Loha Mechinike lisebelisoa tsa bohlokoa indastering ea masela, e khonang ho hlahisa masela a boleng bo holimo a terry bakeng sa lits'ebetso tse fapaneng. Ts'ebetso ea tlhahiso e kenyelletsa ho lokisa thepa ka hloko, ho seta mochini ka nepo, ho loha ho tsoelang pele, taolo ea boleng le ho e lokisa ka morao. Mechini ena e sebetsa ka mokhoa o fapaneng haholo 'me e sebelisoa ka har'a liaparo, masela a lapeng le masela a tekheniki. Ka ho utloisisa ts'ebetso ea tlhahiso, likarolo, tlhophiso, ts'ebetso, tlhokomelo, le ts'ebeletso ea morao-rao ea thekiso, bahlahisi ba ka ntlafatsa ts'ebetso ea bona le ho fihlela litlhoko tse fapaneng tsa mmaraka oa masela.

Nako ea poso: Apr-15-2025